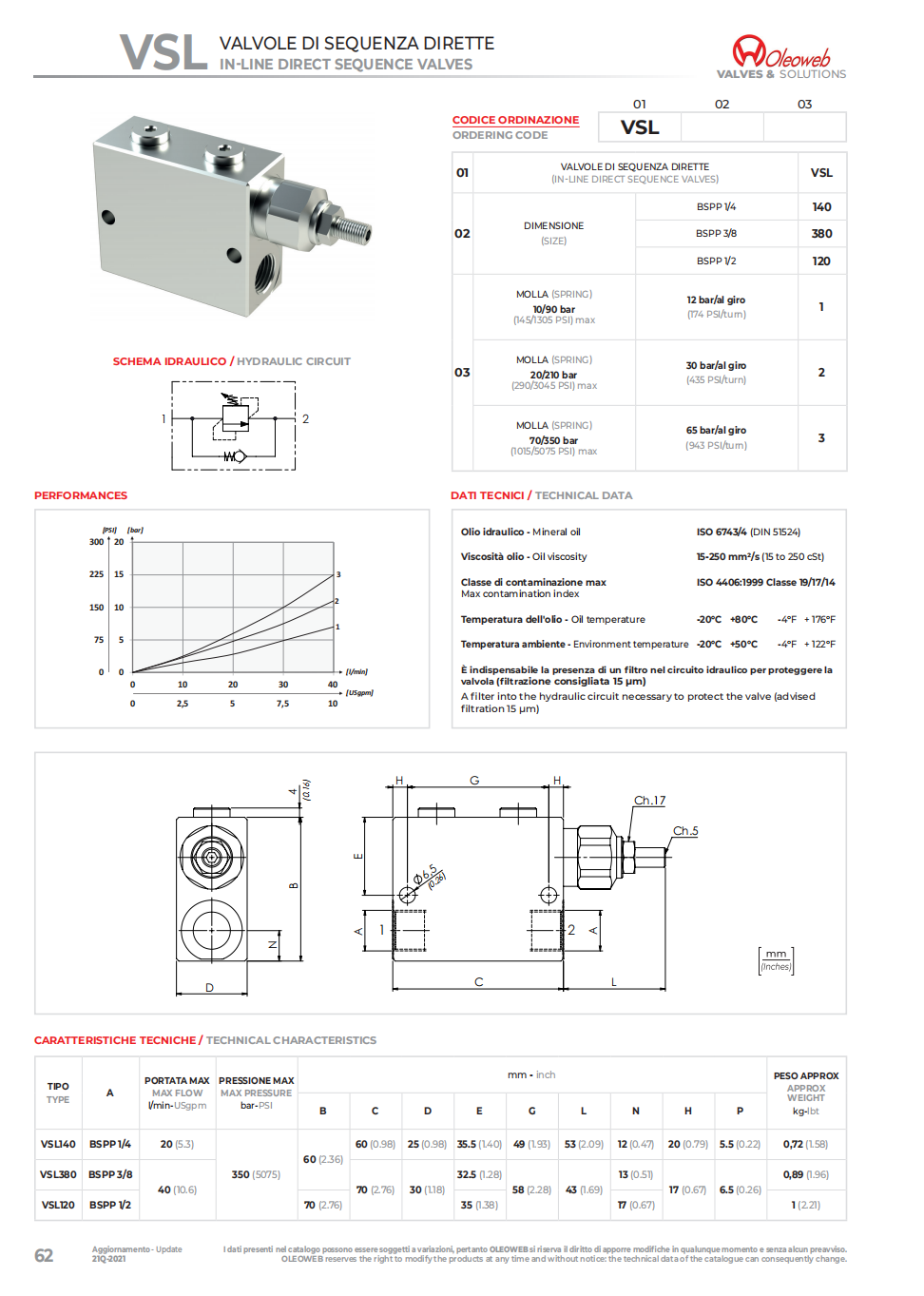

Within a hydraulic system, VSL valves are used to manage actuation sequences of one or more actuators through the appropriate setting of the valve itself. A typical application is the creation of extension sequences of multiple hydraulic cylinders, where one cylinder extends only when the previous one has reached the end of stroke. The VSL valve is unidirectional, the backflow is free. The valve can work with recommended maximum flow rates of 40 lpm (10,6 gpm) and maximum pressures of 350 bar (5075 PSI). The parts-in-body execution allows its installation in line inside the hydraulic system. The body and all external components are made of high-strength steel and zinc-plated in order to resist the action of corrosive agents. The internal components are also made of steel, hardened and grinded where necessary to ensure the correct performance level of the valve.